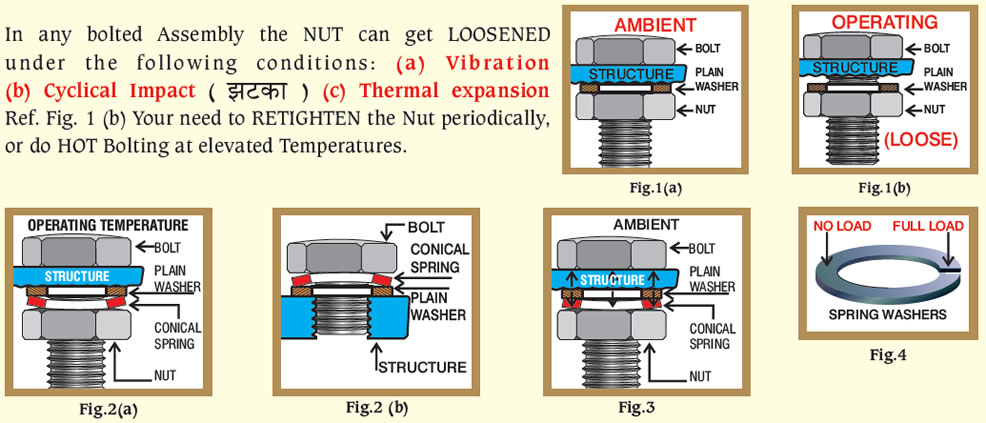

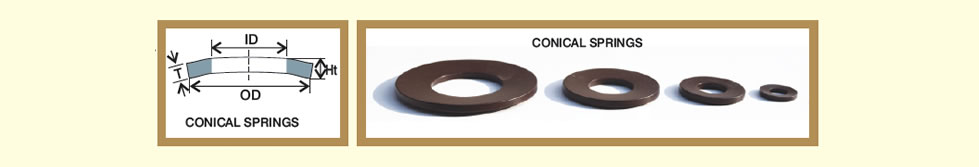

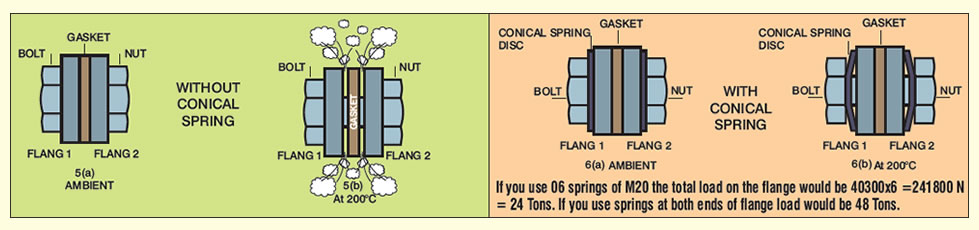

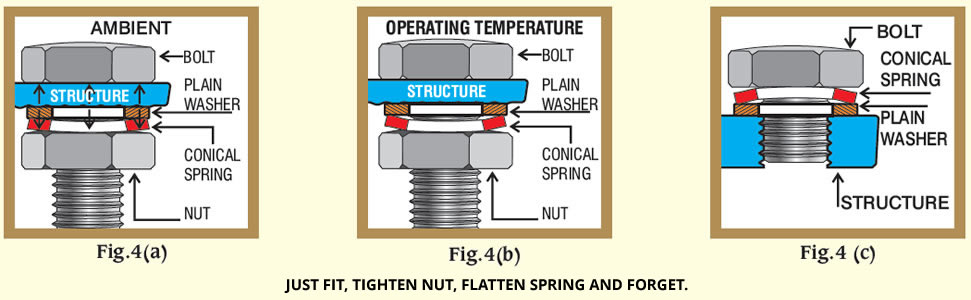

A Simple solution is to install a HEAVY DUTY CONICAL SPRING between NUT and STRUCTURE. Ref. Fig. 2 (a), 2(b). The conical spring is to be TOTALLY FLATTENED. Ref. Fig.3. The conical spring will COMPLETELY PREVENT LOOSENING OF NUT under Vibration, Impact and Thermal Expansion. Unlike spring washers conical Springs EXERT UNIFORM LOAD and the load capacity is 5-10 times of spring washers. Ref. Fig. 4 MOC : Spring steel for temp upto 150 ºC, Chrome vanadium steel for temp. up to 250 ºC. Each spring is coated for marine grade corrosion resistence. These conical springs can be REUSED ANY NUMBER OF TIMES, thus they are a ONE TIME INVESTMENT

| CONICAL SPRINGS MODEL SELECTION CHART | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Notes :

1. We recommend you use minimum 8.8 grade (high Tensile) Fastners to use conical Springs.

2. Apply a small amount of grease to Nut / Bolt before Tightening.

3. In many applications CHROME VANADIUM conical springs can eliminate HOT BOLTING IN FLANGES, HEAT EXCHANGERS & VALVE BONNETS, Etc.

If you install a HEAVY DUTY conical spring between the NUT and BOLT below the structure it ensures the NUT is UNDER CONSTANT TENSION THUS PREVENTING IT FROM LOOSENING. In many countries these springs are therefore called TENSION SPRING. The conical spring is to be Fully FLATENED. Ref Fig 4 (a). The conical spring

will adjust itself against thermal expansion Ref Fig. 4 (b). but ENSURES THAT BOLT / NUT ASSEMBLY does not get LOSENED. NO NEED FOR PREQUENT RITIGHTENING. The conical spring is made from high grade spring steel, heat treated and COATED WITH SPECIAL CORROSION RESISTANT POWDER COATING (96 HOURS SALT SPRAY TEST) . You can retighten it any number of times (in case the equipment is sent for maintenance or overhaul.) The conical spring thus has a LIFE of several years.

SPRING WASHERS VS CONICAL SPRINGS

Conventionally Industry has been using Spring washers to tighten NUT/BOLTS. These Spring washers DO NOT EXERT A UNIFORM LOAD because of their geometry Ref. Fig. 5. CONICAL SPRINGS EXERT AN UNIFORM LOAD ALONG THE PERIPHERY. Moreover the LOAD EXERTED BY CONICAL SPRINGS IS SEVERAL TIMES HIGHER than springs washers. It is for these reasons springs washers are slowly getting phased out in Advanced countries.

| CONICAL SPRINGS MODEL SELECTION CHART | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Notes :

1. We recommend you use minimum 8.8 grade (high Tensile) Fastners to use conical Springs.

2. Apply a small amount of grease to Nut / Bolt before Tightening.

3. Max temperature of conical Spring is 150°C for Alloy spring steel, 250°C for chrome vanadium spring steel

4. In many applications CHROME VANADIUM conical springs can eliminate HOT BOLTING IN FLANGES, HEAT EXCHANGERS & VALVE BONNETS, Etc.

© 2023 All Rights Reserved By Ekta Enterprises