An attempt should always be made to dismount any machine element including bearings, pulleys, couplings and gears without damaging them, especially where the intention is to remount them.

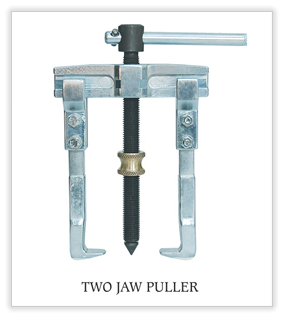

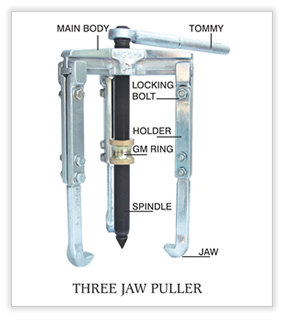

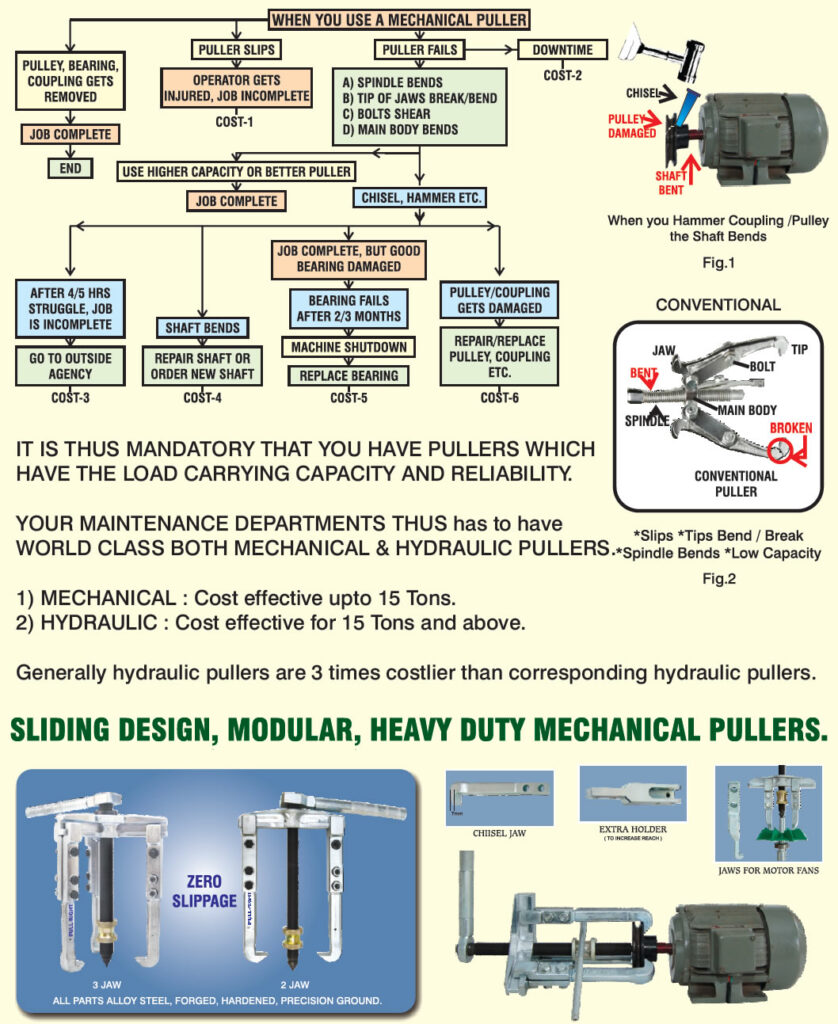

Most of the pullers available today have serious limitations since the jaws slip, tip of jaws bend/break, threads of spindle gets damaged. PULL RIGHT EXTRACTORS overcome all these limitations of conventional pullers.

The major advantages of these pullers are :

(1) The two/three jaws slide backward/forward on precision ground Tee section. The jaws are coplanar over the entire width thus ensuring FULL GRIP over the machine element requiring extraction.

(2) There is a facility of locking puller jaws to avoid any SLIPPAGE while extracting machine elements like bearings, pulleys, couplings etc.

(3) All parts are made from high-grade alloy steel, toughened to 25-30Rc and precision ground to maintain parallelism of jaws. Spindle is of EN 24 and Nitrided. This ensures high LOAD CARRYING CAPACITY and also gives long life to the puller.

(4) There is a rotating center to reduce damage to shaft. A specially designed Tommy is provided to apply extra torque required to remove jammed pulleys/couplings. A gunmetal ring has also been provided to eliminate damage to spindle.

| Table I Two Jaw Extractors | ||||

| MODEL | MIN.

DIA mm |

SPREAD mm |

REACH mm |

WITHDRWAL LOAD kg. |

| P01 | 20 | 100 | 130 | 1500 |

| P02, P03, P04 | 30 | 150 | 200, 250, 300 | 5000 |

| P05, P06, P07 | 30 | 200 | 200, 250, 300 | 5000 |

| P08, P09, P10 | 50 | 250 | 200, 250, 300 | 8000 |

| P11, P12, P13 | 50 | 300 | 200, 250, 300 | 10000 |

| P14, P15, P16 | 50 | 300 | 200, 250, 300 | 10000 |

| Table I Two Jaw Extractors | ||||

| MODEL | MIN.

DIA mm |

SPREAD mm |

REACH mm |

WITHDRWAL LOAD kg. |

| P20 | 030 | 120 | 150, 150 | 3000 |

| P21, P22, P23 | 050 | 150 | 200, 250, 300 | 7500 |

| P24, P25, P26 | 050 | 200 | 200, 250, 300 | 10000 |

| P27, P28, P29 | 070 | 250 | 200, 250, 300 | 12000 |

| P30, P31, P32 | 080 | 300 | 200, 250, 300 | 15000 |

| P33, P34, P35 | 100 | 450 | 200, 250, 300 | 20000 |

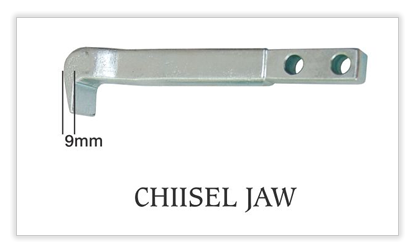

1) CHISEL JAWS :

Many a times there is not enough space behind bearing, gears etc. to accommodate jaws of existing pullers. We offer chisel type jaws which are fully interchangable with standard jaws. These Chisel jaws are common for all models except P01, P20. Chisel jaws are not required for model P01 & P20. Two jaw pullers would require 02 chisel jaws, whereas three jaw pullers would require 03 chisel jaws. Load carrying capacity of these chisel jaws would be 50% of standard jaws.

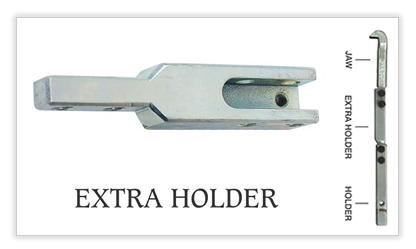

2) EXTRA HOLDERS :

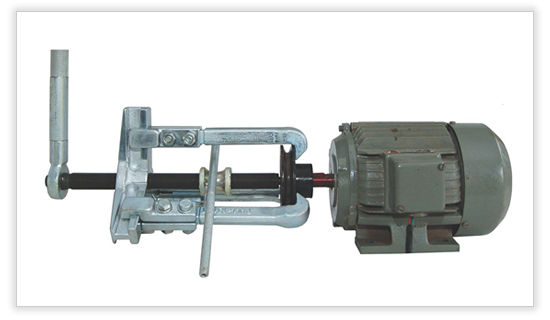

In many applications reach of standard puller is insufficient since distance between edge of shaft and bearing etc. is large. We can offer extra holders to extend reach. (two holders for 02 jaw puller and three holders for 03 jaw puller). Along with extra holders a rotating distance piece is given to extend length of spindle. These extra holders are available for 100mm, 150mm & 200mm length. We can thus get a maximum reach of 500mm.

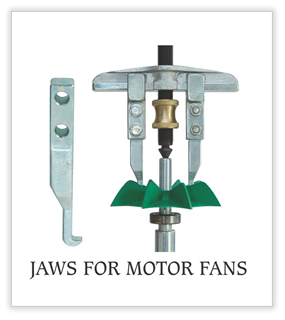

3) JAWS FOR MOTOR FANS :

These are specially made to dismount fans of motors. Normally motor fans have two slots. These slots can be square, round or triangular. The tip of the jaw can accommodate slot size of 8mmx8mm. These fan jaws are totally interchangeable with standard jaws. These jaws have low load carrying capacity and should only be used for removing motor fans. These fan jaws are suitable for only two jaw pullers since motor fans have only 02 slots. Fan jaws are separate for P01 & common for all other two jaw models.

4) ‘C’ WASHERS :

While extracting bearings with bore of 50mm and above there is a possibility of damaging the bearing since load is applied on outer ring. A practical solution is to insert a ‘C’ washer behind the bearing and put jaws of puller over it. These ‘C’ washers are made from alloy steel, hardened , ground and individually numbered according to bearing size for identification. Hence please specify bearings you wish to cover. e.g.-1. For bearing 6313, ‘C’ Washer is designated as 65-140. e.g.-2. For bearing 6319, `C’ Washer is designated as 95-200. The first digit is bearing I.D, the second digit is bearing O.D.

TO DISMOUNT ANY M/C ELEMENT YOU NEED A MECHANICAL / HYDRAULIC PULLER

When you use a Puller ONLY TWO THINGS HAPPEN

(a) The element i.e. bearings, couplings, pulleys, gear gets dismounted.

(b) The puller gets DAMAGED/SLIPS Ref. Fig.2

© 2023 All Rights Reserved By Ekta Enterprises