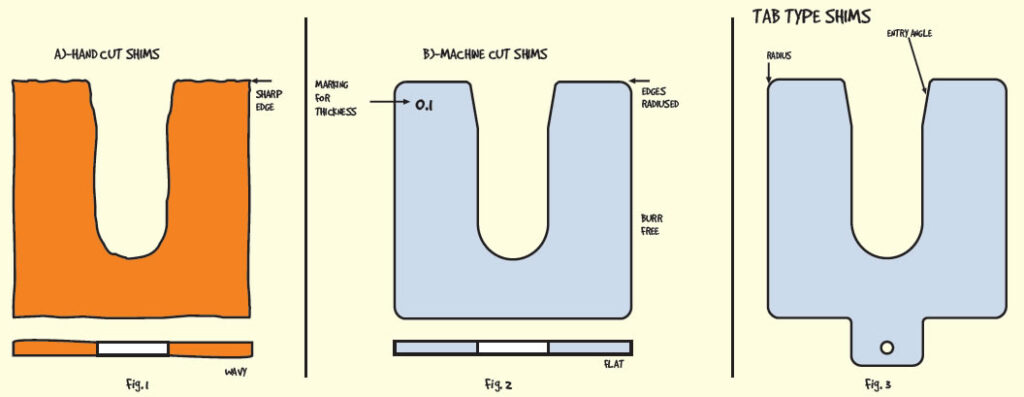

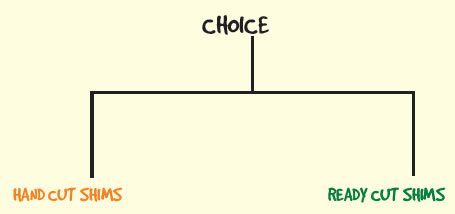

QUALITY EVALUATION OF HAND CUT VS READY CUT SHIMS :-

Hand cut shims are not flat and can give erroneous results.

Hand cut shims have sharp edges and hence risky in handling.

Your skilled technician can get hurt

In hand cut shims, since there is no marking of thickness,

EACH SHIM HAS TO BE INDIVIDUALLY MEASURD FOR THICKNESS.

This is time consuming and a costly affair.

IT IS FOR THIS REASON THAT WORLDOVER, PLANT ENGINEERS HAVE SHIFTED TO READY CUT SHIMS.

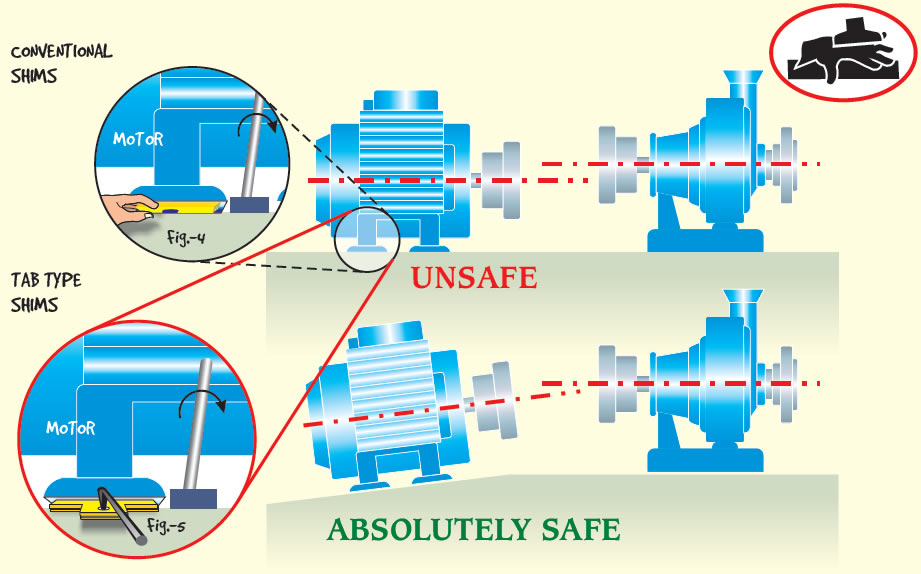

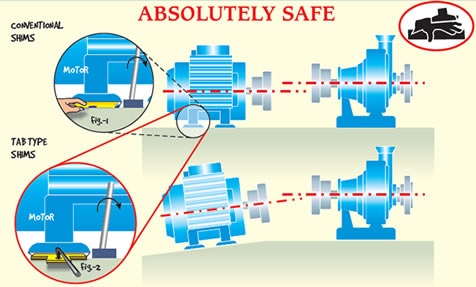

In fact the current trend is to use ready cut but tab type shims. Ref. Fig. 5. The reason is that tab type shims are safer to install & remove.

These are ready cut Shims with OR WITHOUT A Tab. They are made from Die punch Process and are burr free / Flat. Each shim is individually numbered for Thickness, hence identifying them while doing Alignment is accurate and fast.

Alignment kit model |

Coupling Type | Size | Rated Torque Nm | Ø B (Hub) | Remarks |

| AO RANGE 30-60 mm |

L RRL RRS |

30 50 70 75 95 99 |

0.38 2.08 4.90 9.80 21.1 35.1 |

16 27 36 44.5 49 51 |

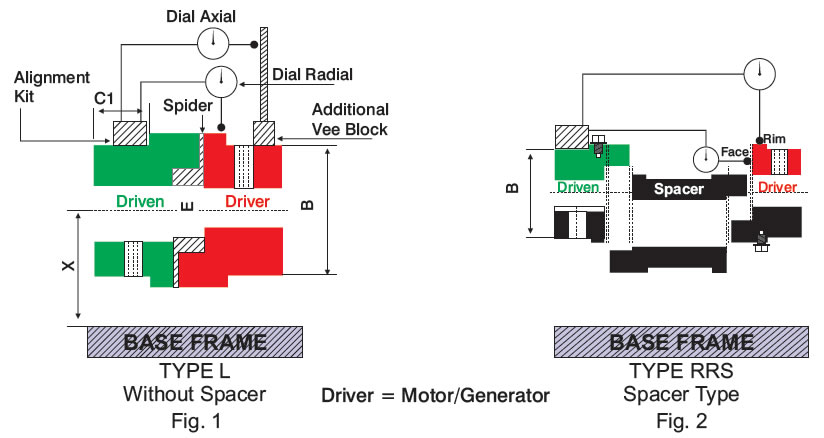

Alignment kit is fixed on Hub Ø B Of couplings & driver v/s driven couplings are Aligned for both Redial, Axial misalignment. In case of RRS / RRL coupling you can remove spacer and do RIM / FACE Method of Alignment Ref. Fig.2. For 'L' type coupling you need additional Vee block for doing axial alignment. Ref. Fig.1. |

| A1 RANGE 40-80 mm |

L RRL RRS |

100 100A 110 150 |

46.4 46.4 89.0 141 |

65 57 76 80 |

|

| A2 RANGE 55-120 mm |

L RRL RRS |

190 225 226 |

190 265 317 |

102 111 119 |

|

| A3 RANGE 70-180 mm |

L RRL RRS |

276 280 295 2955 |

527 768 1279 2132 |

127 140 162 180 |

|

| A4 RANGE 120-250 mm |

300 350 |

3047 4308 |

180 200 |

IEC |

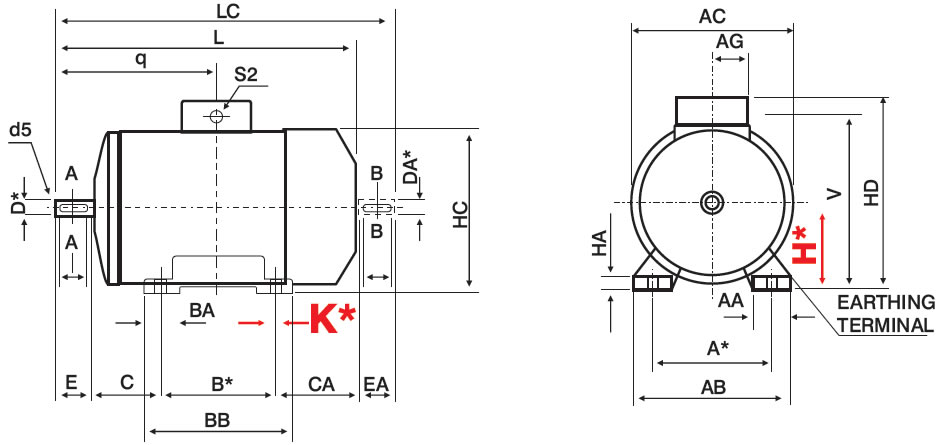

FIXING | GENERAL | BOLT SIZE | RATED OUTPUT | ||||

| Fr. | K* | AA | BA | df | KW | HP | Shim | Slot Size |

| 80 | 10 | 31 | 35 | M10, 3/8 | 0.37 | 0.5 | #1 | 12 |

| 90S | 10 | 34 | 31.5 | M10, 3/8 | 0.75 | 1 | #1 | 12 |

| 90L | 10 | 34 | 31.5 | M10, 3/8 | 1.1 | 1.5 | #1 | 12 |

| 100L | 12 | 43.5 | 36 | M12,1/2 | 1.5 | 2 | #2 | 15 |

| 112M | 12 | 47 | 36 | M12,1/2 | 2.2 | 3 | #2 | 15 |

| 132S | 12 | 64 | 50 | M12,1/2 | 3.7 | 5 | #2 | 15 |

| 132M | 12 | 64 | 54 | M12,1/2 | 5.5 | 7.5 | #2 | 15 |

| 160M | 16 | 58 | 70 | M16, 5/8 | 7.5 | 10 | #2 | 15 |

| 160L | 16 | 58 | 70 | M16, 5/8 | 9.3 | 12.5 | #3 | 20 |

| 180M | 16 | 65 | 70 | M16, 5/8 | 11 | 15 | #3 | 20 |

| 180L | 16 | 65 | 70 | M16, 5/8 | 15 | 20 | #3 | 20 |

| 200L | 20 | 85 | 85 | M20, 3/4 | 18.5 | 25 | #4 | 27 |

| 225S | 20 | 85 | 85 | M20, 3/4 | #4 | 27 | ||

| 225M | 20 | 85 | 85 | M20, 3/4 | 30 | 40 | #4 | 27 |

| 250M | 26 | 100 | 115 | M24, 1 | 37 | 50 | #5 | 30 |

| 280S/M | 26 | 100 | 110 | M24, 1 | 45 | 60 | #5 | 30 |

| 315S/M | 26 | 100 | 115 | M24, 1 | 75 | 100 | #5 | 30 |

| 315L | 26 | 120 | 120 | M24, 1 | 132 | 175 | #5 | 30 |

| K = Hole size in foot, AA BA = Foot Dimension Note : The slot in the shim should be at least 2-3 mm more than bolt size otherwise it becomes difficult to insert & take out the shim. For M12 bolt slot - size recommended is 15mm. * This data is for EEF motors. Bharat Bijlee * The shim should cover the foot of motor completely. |

||||||||

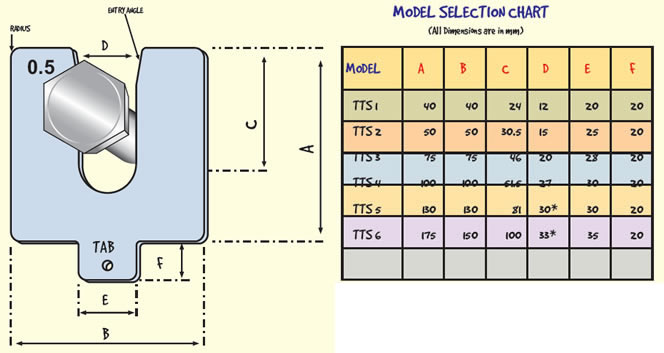

These are ready cut Shims with a Tab.They are made from Die punch Process and are burr free / Flat. Each shim is individually numbered for Thickness, hence identifying them while doing Alignment is accurate and fast.

The advantage of Tab is that the operator can remove these Shims by using a bent Pin, Ref. Fig-2. A 3mm hole has been provided for this purpose. In conventional square / rectangular Shims operator has to put his finger to remove Shims. This is extremely risky since mostly motor is lifted manually and operators fingers are directly below the foot of the motor Ref. Fig-1. A mishap can allays happen This is the reason plant engineers the world over have shifted to ready cut but tab type Shims, although these are costlier.

We offer the following models. To select the correct model you need to know the bolt size slot size, viz ‘D’ should be slightly more than bolt size.

*We can give in higher sizes also. eg.1 TTS 5 can be given in slot size 46mm, TTS 6 in 58mm etc.

THICKNESS (STANDARD*) : 0.05, 0.1, 0.2, 0.5, AND

1.0 mm MATERIAL : STAINLESS STEEL : SS304

*Other thickness can be offered as per customer specifications

© 2023 All Rights Reserved By Ekta Enterprises