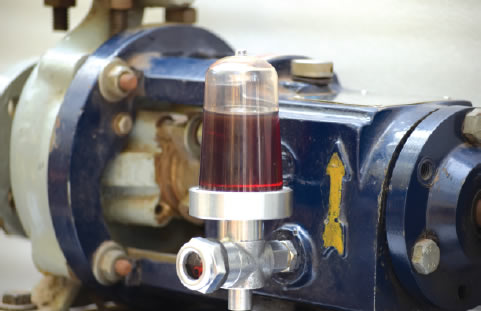

MAINTAINS CONSTANT LEVEL OF OIL IN PUMPS AND OTHER OIL LUBRICATED MACHINES

Constant Level Oiler

In many oil lubricated machines it is essential to maintain a constant level of oil to properly lubricate machine elements in motion. Excessive oil level increases resistance resulting in higher oil temperature. This causes faster ageing and breakage of oil seals, which means frequent oil leakages. Low oil level is a sure recipe for equipment failure.

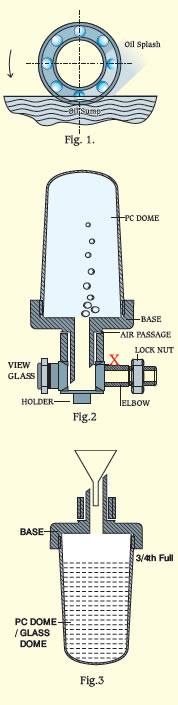

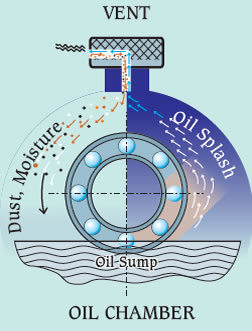

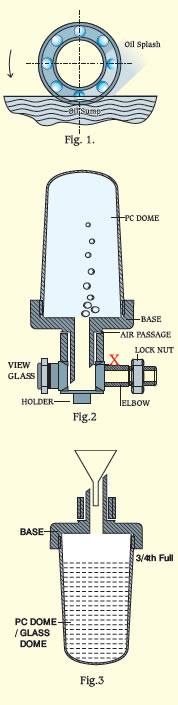

Generally a constant level of oil is required wherever ‘SPLASH’ Lubrication is used. Splashing would occur if part of rotating element is in oil and part is above the oil. Generally it is 1/3 to 1/2 the bottom rolling aliment Ref. Fig. 1

Lubex JOINTLESS DESIGN CLO with view glass has the advantage of zero leakage since there are no joints. THE VIEW GLASS PROVIDES ON LINE VISUAL INDICATION OF OIL LEVEL IN THE SUMP AND ALLOWS TO VISUALLY INSPECT QUALITY OF OIL.

The PC/GLASS dome is threaded and can be cleaned periodically if required. The entire design is totally modular, thus any individual component of the oiler can be replaced at any point of time.

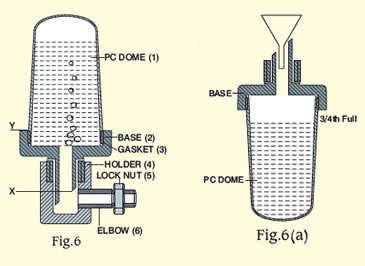

The working principle of ‘LUBEX’ constant level oiler is extremely simple. As and when oil level falls below level ‘x’ air passage is opened, you will notice bubbling taking place within PC dome. Oil flows from PC/GLASS dome in to the machine causing oil level to rise within the machine. The moment oil level in the equipment reaches level ‘x’ air passage is blocked bubbling stops and oil from PC / GLASS dome stops going into the machine. Ref. fig .2

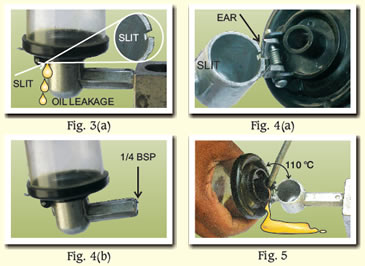

Thus oil in PC/GLASS dome goes on decreasing, but oil within the machine is maintained at a constant level. Oil can be recharged in PC/GLASS dome at any point of time by simply unscrewing base and refilling PC/GLASS dome with an oil can. Ref. fig.3. The product is designed and manufactured to last for several years, an excellent investment for oil lubricated machines requiring a constant level of oil.

| MODEL | DOME | CAPACITY | BASE/ElBOW | END CONNECTION |

| VG-100 | PC/GLASS | 100ml | Aluminium Alloy | 1/4″, 3/8″, 1/2″ BSP or NPT |

| VG-250 | PC/GLASS | 250ml | Aluminium Alloy | 1/4″, 3/8″, 1/2″ BSP or NPT |

NOTE : PC = Polycarbonate GLASS : Borsilicate glass with metal case

PLEASE SPECIFY END CONNECTION WHILE ORDERING.

A) 1/4, BSP=OD 12.9/13.1mm 19 TPI B) 3/8′, BSP = OD 16.4/16.7mm 19TPI C) 1/2′, BSP = OD 20.7/20.9mm 14TPI

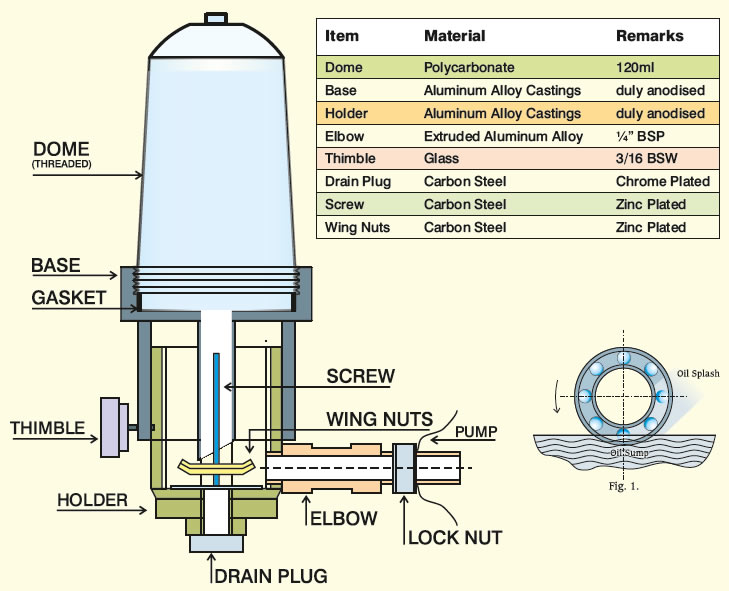

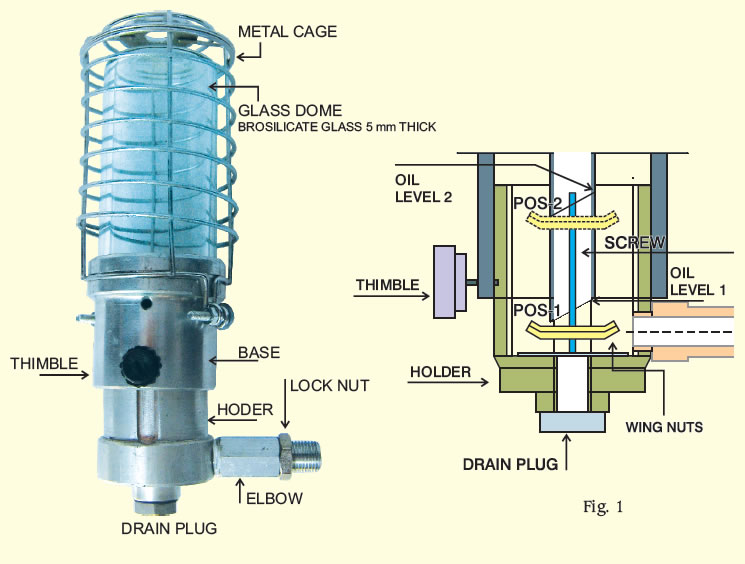

We also offer adjustable heigh oil cup both in PC and Glass

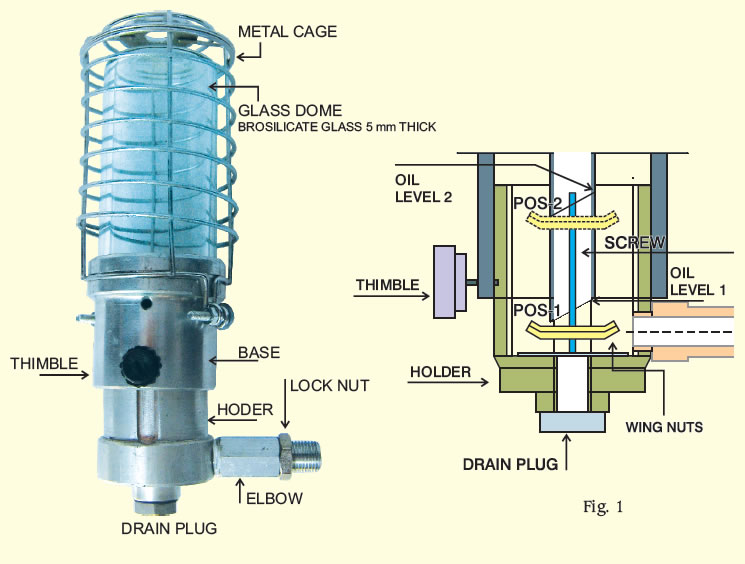

In this design of constant level oiler the height of the cup can be adjusted upward /downward depending on the level of oil required in the bearing housing.

The oil level to be adjusted is generally 1/3 to ½ the bottom rolling element of the bearing. Ref. Fig. 1. The level can be adjusted by opening the cup & taking wing nuts up-down, once height is adjusted the wing nuts are locked. Each time you fill oil in the cup and slide it on the holder wing nuts act like a stopper, moreover the base is secured to the holder by tightening thimble, this ensures that the oil cup does not move up during operation. Old oil can be drained out periodically by opening drain plug.

The advantage of Lubex oil cups is that dome is made of Polycarbonate and threaded. Polycarbonate has excellent impact strength (Virtually unbreakable) good temp stability – i.e. 120°C. Moreover since dome is threaded to base it can be replaced. These oilers are available with glass dome metal cage also.

SHIELDED BREATHER PLUGS

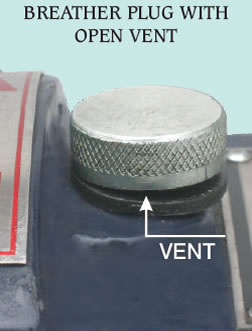

In any pump wherein a constant level oiler (CLO) is installed there is a vent plug (breather plug) either with a vent on the side or bottom. Ref fig.1(a). 1(b). When the pump rotates there is splashing within the oil chamber (ref. Fig 2). This constant Churning of oil at high speed causes an oil/AIR MIST within the oil chamber , which is released trough the vent. However there is always a risk that external contaminants like MOISTURE, FINE SUSPENDED PARTICLES IN THE AIR, FINE DUST etc. could enter in the oil chamber through the vent, THUS CONTAMINATING THE OIL.

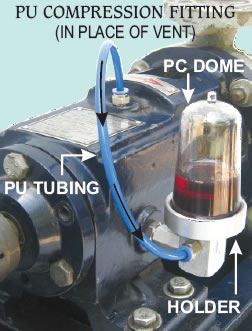

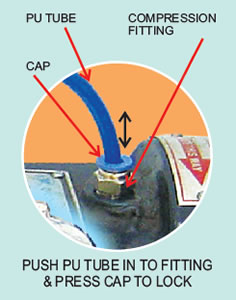

There is always a higher risk of this happening in STAND- BY PUMPS since there is NO INTERNAL PRESSURE WITHIN THE OIL CHAMBER CONTAMINATED OIL REDUCES THE LIFE OF BEARINGS SUBSTANTIALLY. Lubex CLO in closed Loop solves this problem considerably. The vent is replaced by a bushing (generally ½” X ¼”BSP). A PU COMPRESSION fitting with 6mm O.D. PU Tube is fitted in place of the vent plug. The other end of the PU tubing is fixed to the PU COMPRESSION fitting in holder of oiler. This forms a closed loop, wherein the oil AIR MIST comes back to the oiler ref. fig. 3. There is very little chance of external contaminants entering into the oil chamber. This system decreases the FREQUENCY OF OIL CHANGE, REDUCES CONTAMINATION OF OIL AND THUS SIGNIFICANTLY INCREASES LIFE OF BEARINGS. Major Refineries and Petrochemicals plants internationally already have introduced these kinds of devices on their pumps.

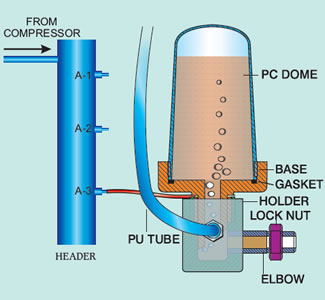

In a few Refineries /Petrochemicals plants they now have an AIR HEADER through which low pressure DRY Lubricated compressed Air is provided to the pump. This totally eliminates Ingress of any contaminant entering through the air passage slots in the oiler. Ref. Fig. 4(a) & Fig. 4(b). This arrangement is not in our scope of supply. THE GOAL IS TO HAVE ENHANCED LIFE OF BEARINGS AND REDUCED FREQUENCY OF OIL CHANGE. SKF and other leading bearing manufacturers are guaranteeing 7-8 years of LIFE. Where are you?

We offer the following models :

MODEL SELECTION CHART

| MODEL | DOME | CAPACITY | BASE/ELBOW | END CONNECTION |

| L-100C1 | PC | 100ml | Aluminium Alloy | 1/4″, 3/8″, 1/2″ BSP |

| L-250C2 | PC | 250ml | Aluminium Alloy | 1/4″, 3/8″, 1/2″ BSP |

MOC of holder, Elbow Extruded Aluminums Alloy

MOC of base – pressure die cast Aluminum

End connections – ¼” BSP / ¼” NPT, other sizes on demand

Note: You need to specify size of existing Breather plug to supply the required Bushing. Our standard PU COMPRESSION size is ¼” BSP with 6 mm PU tubing.

TO INSTALL PU TUBING AT BOTH ENDS, PROCEED

AS PER FIG. 5.

n these type of oilers the height of oil level can be adjusted by raising the wing nuts. Once height is adjusted it is locked by a thimbles. Ref. Fig. 1

| Item | Material | Remarks |

| Dome | Glass | 100ml |

| Base | Aluminum Alloy Castings | duly anodised |

| Holder | Aluminum Alloy Castings | duly anodised |

| Elbow | Extruded Aluminum Alloy | ¼” BSP |

| Thimble | Glass | 3/16 BSW |

| Drain Plug | Carbon Steel | Chrome Plated |

| Screw | Carbon Steel | Zinc Plated |

| Wing Nuts | Carbon Steel | Zinc Plated |

MAINTAINS CONSTANT LEVEL OF OIL IN PUMPS AND OTHER OIL LUBRICATED MACHINES

Constant Level Oiler

In many oil lubricated machines it is essential to maintain a constant level of oil to properly lubricate machine elements in motion. Excessive oil level increases resistance resulting in higher oil temperatur This causes faster ageing and breakage of oil seals, which means frequent oil leakages. Low oil level is a sure recipe for equipment failure.

Generally a constant level of oil is required wherever ‘SPLASH’ lubrication technique is employed. In this system of lubrication rotating element causes a ‘splash’ due to its rotation and this splashed lubricant in turn lubricates all other machine elements within the system. Splashing would occur if part of rotating element is in oil and part is above the oil. Rf. Fig.1

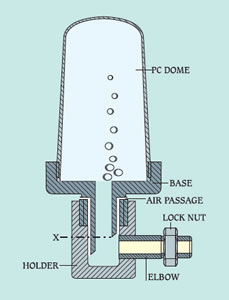

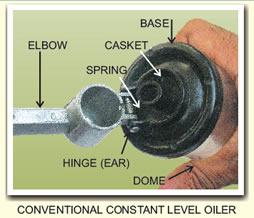

The right answer is to install an efficient, reliable constant level oiler. ‘LUBEX’ constant level oiler consists of a polycarbonate (PC) dome with suitable aluminium alloy base and elbow to fit your equipment. PC has the advantage of extraordinary impact strength (virtually unbreakable), excellent clarity, and good temperature range (110 ° c). A lock nut facilitates keeping the oiler upright without overtightening elbow.

The PC dome is threaded and can be cleaned periodically if required. The entire design is totally modular, thus any individual component of the oiler can be replaced at any point of time.

The working principle of ‘LUBEX’ constant level oiler is extremely simple. As and when oil level falls below level ‘x’ air passage is opened, you will notice bubbling taking place within PC dome. Oil flows from PC dome into the machine causing oil level to rise within the machine. The moment oil level in the equipment reaches level ‘x’ air passage is blocked bubbling stops and oil from PC dome stops going into the machine. Ref. fig.2

Thus oil in PC dome goes on decreasing, but oil within the machine is maintained at a constant level. Oil can be recharged in PC dome at any point of time by simply unscrewing base and refilling PC dome with an oil can. The product is designed and manufactured to last for several years, an excellent investment for oil lubricated machines requiring a constant level of oil.

| MODEL | DOME | CAPACITY | BASE/ElBOW | END CONNECTION |

| L-100 | PC | 100ml | Aluminium Alloy | 1/4″, 3/8″, 1/2″ BSP |

| L-101 | PC | 100ml | SS 304 | 1/4″, 3/8″, 1/2″ BSP |

| L-250 | PC | 250ml | Aluminium Alloy | 1/4″, 3/8″, 1/2″ BSP |

NOTE : PC = Polycarbonate

PLEASE SPECIFY END CONNECTION WHILE ORDERING.

A) 1/4, BSP=OD 12.9/13.1mm 19 TPI B) 3/8′, BSP = OD 16.4/16.7mm 19TPI C) 1/2′, BSP = OD 20.7/20.9mm 14TPI

We also offer adjustable heigh oil cup both in PC and Glass

The importance of reliable (CLO)

© 2024 All Rights Reserved By Ekta Enterprises