Monitoring and Maintaining oil level in Gear Boxes is bit of a problem.

There are Primarily two methods of inspecting oil level in Gear Boxes.

A) DIP STICK: Gear box manufacturers provide a Dip Stick on top of Gear Box. This dip stick has two markings viz. ‘HI’ & `L0′. Ref. Fig. 1. When gear box is not running oil level has to be at HI, whenever oil level goes below `LO’ oil has to be added. The difficulty is how to know whether oil level has gone below `L0′. Stopping the gear box to check oil level is neither convenient nor practical. Gear Boxes are often located at odd locations wherein operators seldom check Oil. In a typical process plant there are dozens of gear boxes, maintaining oil level with Dip Stick technology is a herculean task. There is a definate chance that a few gear boxes are running even below ‘LO’ oil Level. The cost of breakdowns, replacement of expensive gears and bearings are indeed phenomenal.

B) Oil Level Window (SIGHT GLASS): A threaded glass based oil level window is fixed in Gear Box. Ref. Fig. 2. The level to be maintained is marked on the glass. These oil windows become blackish over a period of time, making it difficult to visually inspect oil level. There is always a risk that proper oil level is not being maintained. With both these conventional methods there is considerable guess work associated with monitoring of proper oil level in Gear Boxes. Lubex oil level indicators offer a simple, cost effective solution.

All you need to do is remove drain plug of Gear Box, fix a suitable adaptor (Straight/90°) and install a Lubex Oil Level Indicator.

OIL LEVEL INDICATOR

Lubex oil level indicator (OLI) consists of a polycarbonate tube, an aluminum alloy holder* with built in drain plug and an elbow of suitable length. Ref. Fig. 4. The elbow has a standard end connection of 1/4″ BSP.

Once OLI has been installed, you will need to mark ‘HI’ / level on indicator tube. This has to be done with reference to ‘HI’ / ‘1,0’ on Dip Stick or Oil Sight level Window.

Polycarbonate (PC) tube of Lubex OLI offers excellent visibility PC is virtually unbreakable & has excellent temperature stability (110° C). Once installed Lubex OLI would last several years thus making these oil level indicators an excellent investment with pay back of a few weeks.

ORDERING CODE: Please specify the following.

1) Tube Length: ’12 Standard Lengths are 100mm, 200mm, 300mm & 500mm

2) Thread size : ‘T’ of Drain Plug eg. 1/2″ BSP

3) Length : ‘H’ of Elbow. Standard lengths are 25mm, 50mm, 75mm & 100mm

e.g. L = 200mm, T = 3/8″ BSP, H = 25mm

* Holder/Elbow can be offered in SS304 also.

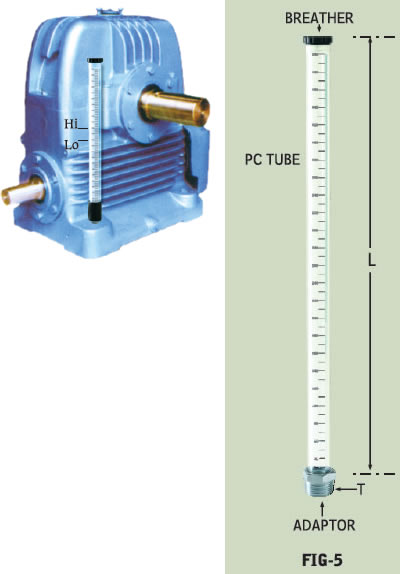

OIL LEVEL INDICATOR – TYPE II FOR DAY TANKS, COOLING TOWER GEAR BOXES

In many applications a Day Tank is fabricated for storing furnace oil, fuel oil etc. In these applications oil is filled via a pump and stored in a day tank. Oil is supplied by Gravity to furnace/ engine etc. Measuring oil level in these day tanks requires an operator to physically inspect oil level with dip stick etc. Similarly in cooling tower gear boxes a dip stick is provided. We have already discussed disadvantages of monitoring oil level with dip stick.

A simple solution is to install a Lubex Oil level Indicator with straight adaptor. Ref. Fig. 5. These oil indicator tubes are available in standard lengths of 300mm, 500mm, 700mm & 1.0 mts. If day tank height is more than 1.0 meter you may need to fix two tubes.

Type-II OLI has to be fixed to the day tank by using a suitable elbow & Flange/Hex Nipple. This is not in our scope of supply and has to be done by you at your end.

In cooling tower gear boxes you can fix type II OLI to bottom elbow of the extension pipe of gear box.

Ordering Code 1.) Length `U of tube 2.) Adapter size ‘T’

e.g. L = 500mm T = 1″ BSP

These knob type level indicators find extensive use in gear boxes, compressors and other oil lubricated equipment. In case the glass gets dirty or damaged the Indicator has to be unscrewed and replaced. We offer the following standard sizes. Other sizes will have to be ordered by specifying thread size.

© 2024 All Rights Reserved By Ekta Enterprises