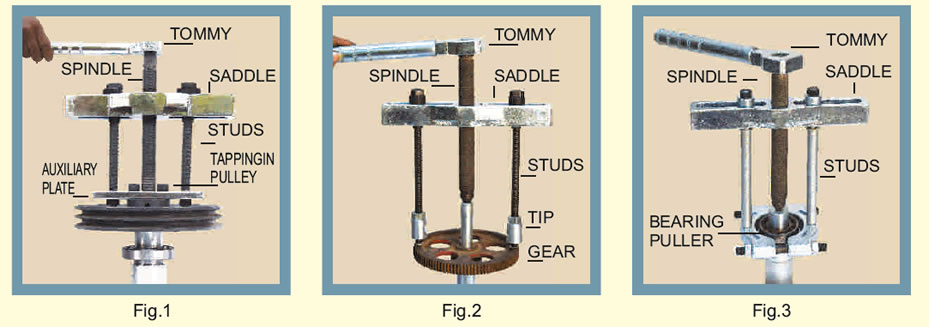

They are excellent Tools for Dismounting GEARS, PULLEYS, IMPELLERS, and BLOWERS etc.

If these elements have a Tapping they can directly be dismounted using these extractors, otherwise you will need to Drill & Tap two holes. If this is not possible a temporary NUT can be welded, and removed after Dismounting. The HIGH-TENSILE BOLTS/STUDS can be adjusted in the SADDLE by sliding them. Suitable Tips can be used as per tapping available in machine element.

Force can be applied manually by spindle/Tommy or by using a Hydraulic jack. All parts are made from High grade ALLOY STEEL, Heat treated and plated for corrosion prevention.

You can use a Bearing puller attachment Ref. Fig 3 to dismount Bearings having very little clearance behind them. This is made from FORGED and Hardened Alloy Steel to give excellent load carrying capacity.

| Model | Min SpreadMax. |

Spread |

Std. Reach |

Tips | Capacity) |

| JBE-0 | 44 | 150 | 100 | M6,M8,M10 | 3 Tons |

| JBE-1 | 66 | 205 | 160 | M10, M12, M16 | 8 Tons |

| JBE-2 | 110 | 250 | 210 | M12, M16, M20 | 15 Tons |

| Note: If you cannot adjust MIN SPREAD use an Auxiliary Plate Ref. Fig 1. | |||||

| Model | Min. |

Max. | Capacity |

Recommended Model Min. Max. Capacity Jack Bolt Extractor |

| BP-0 | 6000 ID – 20mm OD – 47mm |

6205 ID- 25mm OD – 52mm |

3 Tons | JBE - 0 |

| BP-1 | 6204 ID – 20mm OD – 47mm |

6307 ID- 35mm OD – 80mm |

8 Tons | JBE - 1 |

| BP-2 | 6308 ID – 40mm OD – 80mm |

6318 ID- 90mm OD – 190mm |

15 Tons | JBE - 2 |

| NB EXTRA REACH CAN BE PROVIDED AS PER YOUR REQUIREMENTS. | ||||

© 2024 All Rights Reserved By Ekta Enterprises